Keeping Smart-Factory Tablets Online: A Practical Guide to Rugged Mobility

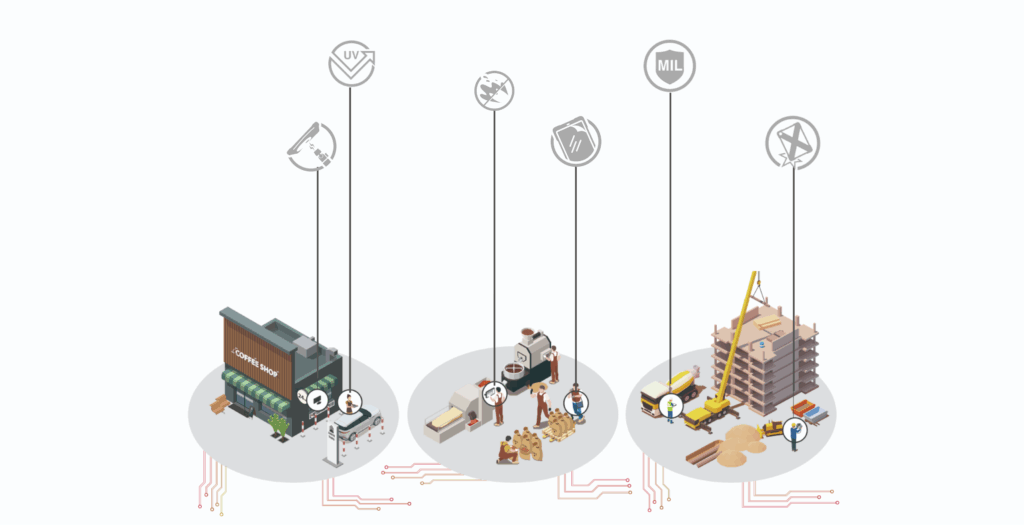

In today’s smart factories, tablets are mission-critical – powering digital work instructions, MES dashboards, and AI-driven analytics. But harsh environments like coolant spray, metal dust, constant vibration, and forklift traffic can knock consumer-grade devices offline in weeks.

When every minute of downtime chips away at OEE and throughput, protecting tablets isn’t a luxury – it’s a necessity.

Why This Matters Now

- M2M data volumes are doubling every 30 months, pushing more decisions to mobile endpoints.

- Hardware budgets are tightening – extending device life is now a strategic priority.

- Lean staffing means fewer hands for emergency device swaps.

1. Map the Hazards Before You Buy

| Work Zone | Common Threats | Business Impact |

|---|---|---|

| CNC & Press Brakes | Coolant spray, metal chips | Corroded ports → device swap, data loss |

| Conveyor Lines & AGVs | Constant vibration | Reboots → production delays |

| Forklift Aisles | Drops, collisions | Broken screens → idle operators |

| Shipping Docks | Dust, temperature swings | Laggy tablets → slower cycle counts |

Pro Tip: Conduct a Tablet Hazard Walk-Through with supervisors. Measure vibration, splash exposure, and drop height in each zone to define your protection spec.

2. Turn Specs Into Business Wins

| Spec / Feature | Operational Benefit |

|---|---|

| MIL-STD-810G (Method 516.6) | Survives 26 drops from 4 ft → fewer replacements |

| IP54 / IP68 Sealing | Blocks dust and fluid → reduces unplanned downtime |

| Sealed Ports & Speakers | No DIY tape hacks → consistent audio/data performance |

| Asset Tag Window | Scan without removing case → faster audits |

| VESA 75 / MagConnect® Mounts | 3-sec dock/undock → less operator wait time |

3. Rugged Deployment Checklist for IT & OT Teams

✅ Specify first, shop later – Add MIL-STD-810G & IP54 to every RFP

✅ Pilot in the harshest zone – Test where splash and vibration are worst

✅ Log uptime for 30 days – Track reboots, drops, and cleanings to justify rollout

✅ Mount > carry – Use articulating arms and HD mounts to reduce drops and fatigue

4. Tech Trends That Raise the Stakes

- Edge AI Vision – Tablets now run defect-detection models locally. Uptime is critical for quality.

- Private 5G & Wi-Fi 7 – Higher bandwidth = more real-time dashboards on mobile devices.

- Battery Health APIs – Predictive analytics only work if the tablet survives long enough to report.

5. What Rugged Cases Can (and Can’t) Do

A rugged case can:

✔ Survive 4-ft concrete drops

✔ Seal against water spray and dust fines

✔ Preserve Wi-Fi, Bluetooth, NFC, and camera performance

✔ Dock securely to VESA 75 or MagConnect mounts

But it can’t:

✘ Provide intrinsic safety (CID2/ATEX)

✘ Withstand high-pressure washdowns (> IP66)

✘ Replace ergonomic planning – heavy tablets still need proper mounting

6. Bringing It All Together

After mapping hazards, translating specs to ROI, and piloting in one line, most plants land on a shortlist of rugged cases that meet MIL-STD-810G and IP54. Use your uptime log and our checklist to compare vendors objectively.

Introducing aXtion Go MP – When You’re Ready

When your criteria are clear, evaluate how the aXtion Go MP for Surface Pro meets every spec – plus adds a lockable stylus and chemically resistant finish.

Watch drop-test videos and pilot results → Product Details

Cut Downtime in 30 Days

Book a 30-minute discovery call to:

- Get a free trial kit (case + HD forklift mount)

- Access the Hazard Walk-Through & Uptime Log

- Benchmark your break/fix spend against lean peers

👉 Reserve your slot: thejoyfactory.com/demo

Learn More

Learn how rugged testing works with Estone Tech’s MIL‑STD‑810G Testing Standards.

Understand IP ratings with Trusted Reviews’ guide to IP54.

See how connected tablets improve productivity in Construction Dive’s industry report.

Explore the benefits of digital work instructions in Azumuta’s Industry 4.0 blog.

Dive into rugged vibration testing with Trenton Systems’ MIL‑STD‑810 overview.

Discover how quick-connect mounting works with The Joy Factory’s MagConnect system.

Ready to learn more?